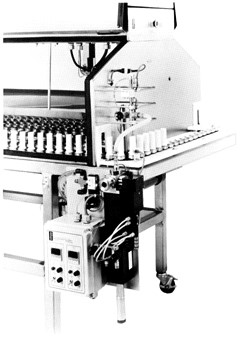

Hot Fill & Cooling Tunnel - Analgesic Stick

R-J Model S3C Serpentine Chain Cooling Conveyor with HEPA Filter System

R-J Model S3C Serpentine Chain Cooling Conveyor with HEPA Filter System

Hinged full length lift up side panels allow easy access to the interior of the cooling chamber for cleaning, sanitation or maintenance work.

A HEPA Filter is installed with stainless steel ducting from the air conditioner to the HEPA unit to filter the recirculating cold air.

All framework and panels are stainless steel.

Precision Series Air Operated Piston Filler with Rotary Valve and Custom Heating for Hot Fill application

The Model CTN Container Tracking Nozzle tracks the container neck during the fill cycle. A container sensor verifies container in place and initiates a fill cycle.

The nozzle mounting is integrated with the cooling tunnel c/w heater and thermocouple to maintain nozzle temperature.

R-J Model AFK Automation Fill Kit c/w container sensor for No Container/No Fill Interlock and controls for all pump functions with manual overrides to facilitate set-up and clean-up operations.

|

R-J Model S3C Serpentine Chain Cooling Conveyor with HEPA Filter System Model shown has 60 feet of cooling conveyor contained within a compact space saving design with a 40" wide X 70" long footprint. Longer conveyors with larger capacity can be designed. The VFD Variable speed drive will provide a conveyor speed of 5 feet per minute which will allow for a 10 minute dwell in the cooling chamber. The variable speed conveyor drive will allow for trim adjustment to suit production needs. All cooling tunnels are custom designed based on the product, temperature range and volume to be cooled. Conveyor lengths, dwell times and temperatures are all taken into consideration. Full width container loading/unloading station allows for ease of container handling. Automatic infeed and discharge Hinged full length lift up side panels allow easy access to the interior of the cooling chamber for cleaning, sanitation or maintenance work. Adjustable stainless steel baffle plates allow cooling air flow to be tailored to suit product cooling characteristics. All framework and panels are stainless steel with heavy duty casters & swivel locks. A top quality commercial air cooling unit is integrated within the main framework to supply a reliable source of filtered cooling air An optional HEPA Filter is installed with stainless steel ducting from the air cooling conditioner to the cooling tunnel with baffle plates to filter the recirculating cold air. |

|

Precision Series Air Operated Piston Filler with Rotary Valve and Custom Heating for Hot Fills Precision Series pumps are manufactured to uncompromising quality standards. Produced using the best materials, advanced manufacturing techniques and rigid Quality Control, Precision Series Metering pumps provide excellent Dispensed volume is easily and precisely adjusted on a convenient micrometer scale. All pumps are adjustable from 10-100% of their range. Volume adjustments can be made R-J Model AFK Automation Fill Kit c/w container sensor for No Container/No Fill Interlock and controls for all pump functions with manual overrides to facilitate set-up and clean-up operations. Custom pump shelf to mount pump on side of cooling tunnel and allow removal of pump unit for independent operation. The pump heater c/w electronic heat control and thermocouple are mounted into a resin enclosure which will be integrated with the pump stand. This allows the Precision Metering Pump to be used totally independent of the cooling tunnel. The Model CTN Container Tracking Nozzle tracks the container neck during the fill cycle. A container sensor verifies container in place and initiates a fill cycle. The nozzle mounting is integrated with the cooling tunnel c/w heater and thermocouple to maintain the nozzle temperature. A smooth, jerk free, continuous motion during the filling and cooling cycle allows for high fill levels and a clean surface finish. |