Precise Small Fill Volumes (0-20ml)

Under Construction...

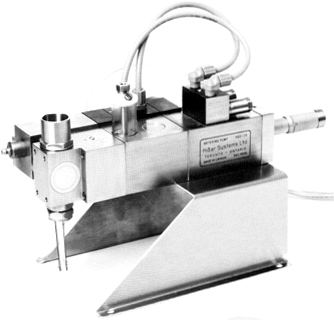

Rotary Style Pump Head for thicker products or products with inclusions

- Mascara

- Pastes

- Adhesives

- Condiments

- Creams

- Cosmetics

- Paints

- Coatings

HIBAR MODEL 2B RV complete with:

- Stainless Steel Sled Base

- Footswitch Actuator

- Air Filter, Regulator, Oiler

- Open Tube Nozzle Assembly

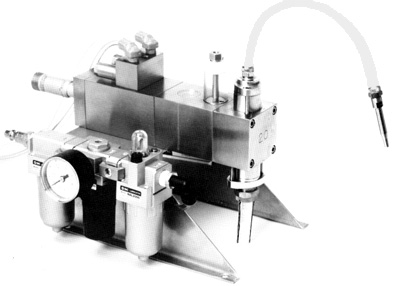

Check Valve Style Pump Head for thinner, free-flowing products:

- Solvents

- Lacquers - Paints

- Cosmetics

- Detergents

- Waxes

- Emulsions

- Glues

- Cyanoacrylates

- Syrups

HIBAR MODEL 2B CV complete with:

- Stainless Steel Sled Base

- Footswitch Actuator

- Air Filter, Regulator, Oiler

- Open Tube Nozzle Assembly

- Bottom Inlet c/w Suction Tubing

STANDARD FEATURES

High Metering Accuracy

Dispensing accuracies of +- 1/2% or better are easily achieved and maintained without readjustment or recalibration.Micrometric Volume Control

Dispensed volume is easily and precisely adjusted on a convenient micrometer scale. All pumps are adjustable from 10-100% of their range. Volume adjustments can be made while the pump is operating.Integral Pneumatic Controls

Pumps are fully self contained units with built-in state-of-the-art pneumatic controls. A start signal (either electric or pneumatic) is all that is required to initiate a full dispense cycle.Precision Speed Controls

Dispensing and suction stroke speeds are precisely controlled by individual pneumatic flow control valves. Micrometer scale adjustments are designed to provide fine speed control over a wide range of dispensing speeds. Speed adjustments are entirely independent of volume adjustment.Long Service Life

Wear free design and use of high quality materials such as Zirconia Ceramic and 316 Stainless Steel provide reliable operation for millions of cycles.Easy to Clean and Maintain

Unique tie rod design holds valve head, pump body and base drive unit accurately aligned. Loosening the tie rods enables the whole pump head to be removed and easily disassembled for cleaning and sterilizing. Additional pump heads allow rapid changeover, one pump being cleaned while the other is in production. The pumps can easily be overhauled in the field by replacing a few inexpensive components.Adaptability for Automation

Precision Series pumps are completely self-contained, ready for installation on virtually any automated liquid dispensing or filling machine. No additional motors, cams or linkages are necessary. Connection to an air supply and provision of a start signal is all that is required for operation.Versatility

A wide variety of fully interchangeable infeed connections and nozzles are easily installed to suit specific applications. Quick interchangeability of these components enables rapid changeover or cleanups. Infeed connections can be set up for hoppers or direct coupling to storage or process vessels. A full range of accessories provide even more versatility.Quality and Service

Precision Pumps are manufactured to uncompromising quality standards. Produced using the best materials, advanced manufacturing techniques and rigid Quality Control, Precision Series Metering pumps provide excellent reliability and performance.STANDARD MODELS

All Models are available in either Check Valve or

Rotary Valve design.Check Valve: 0 - 10,000 cps viscosity liquids

containing no solid particles or fibres

Rotary Valve: Medium to high viscosity liquids

which may contain solid particles or fibres.

Standard wetted materials include 316 Stainless Steel, Zirconia Ceramic, Delrin and Viton. Other specialized materials are available to suit specific applications.

ACCESSORIES AVAILABLE- Positive Shut-off Nozzles

- Heating Packages

- Suckback Units

- Mounting Rigs

- Hoppers

- Mobile Carts-Pump Stands

- Bottom-up Filling Units

- Pressure Feed Systems

- Adjustable Container Platforms