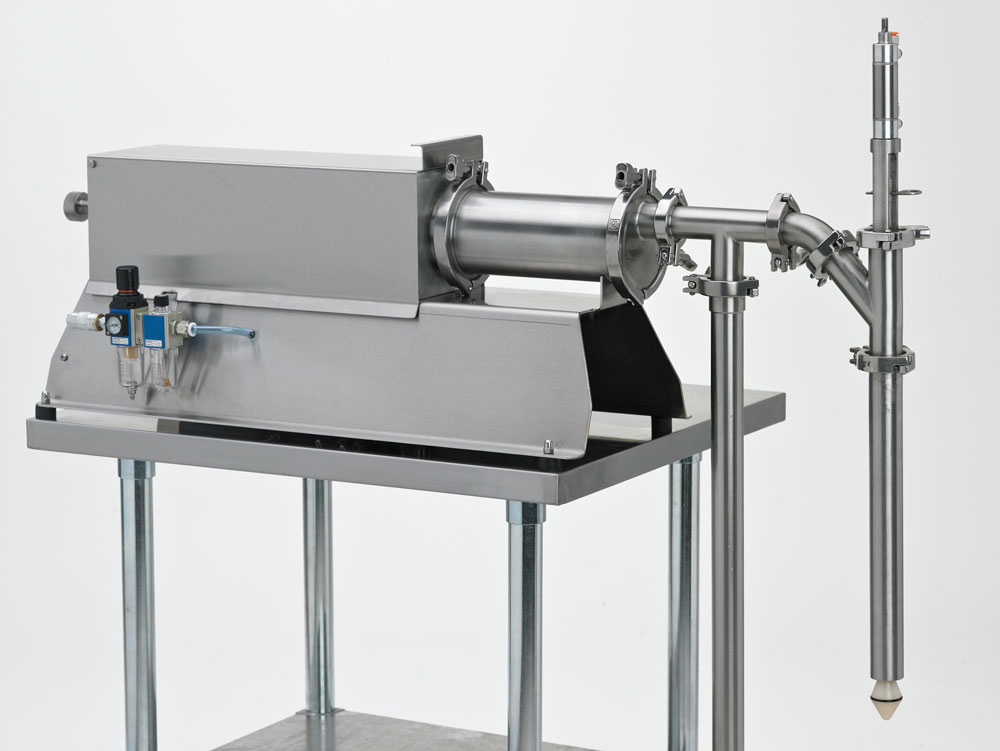

Interchangeable: Nozzle & Pump Head Assemblies

INTERCHANGEABLE: NOZZLE ASSEMBLIES

|

Open Tube Nozzles:

|

Check Valve Style Nozzles: Designed for free flowing products which would dribble from an open tube nozzle. Products: Industrial & Household Chemicals, Cleaners & Detergents, Cosmetic, Shampoo, Conditioners, Creams & Lotions Pharmaceutical & Food & Dairy |

|

Big Port E-Z Flow Sanitary Check Valve:

|

|

|

|

Positive Acting Shut-off Nozzles:

|

|

Internal & External Poppet style:

|

|

|

|

Plug Spout style nozzles for products with particles:

|

|

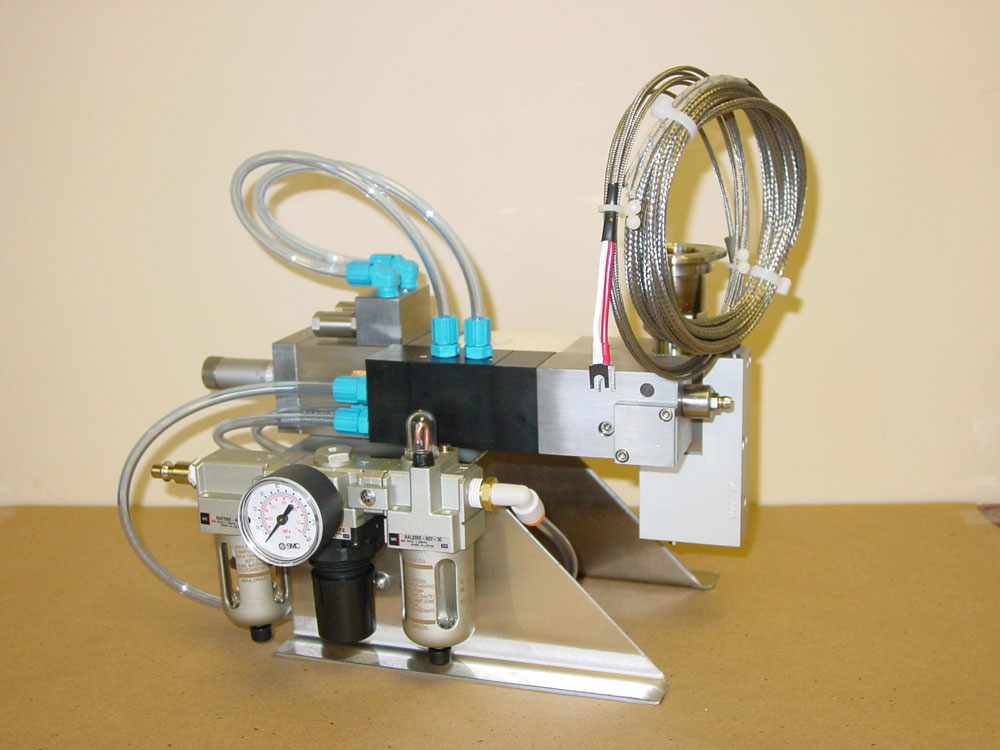

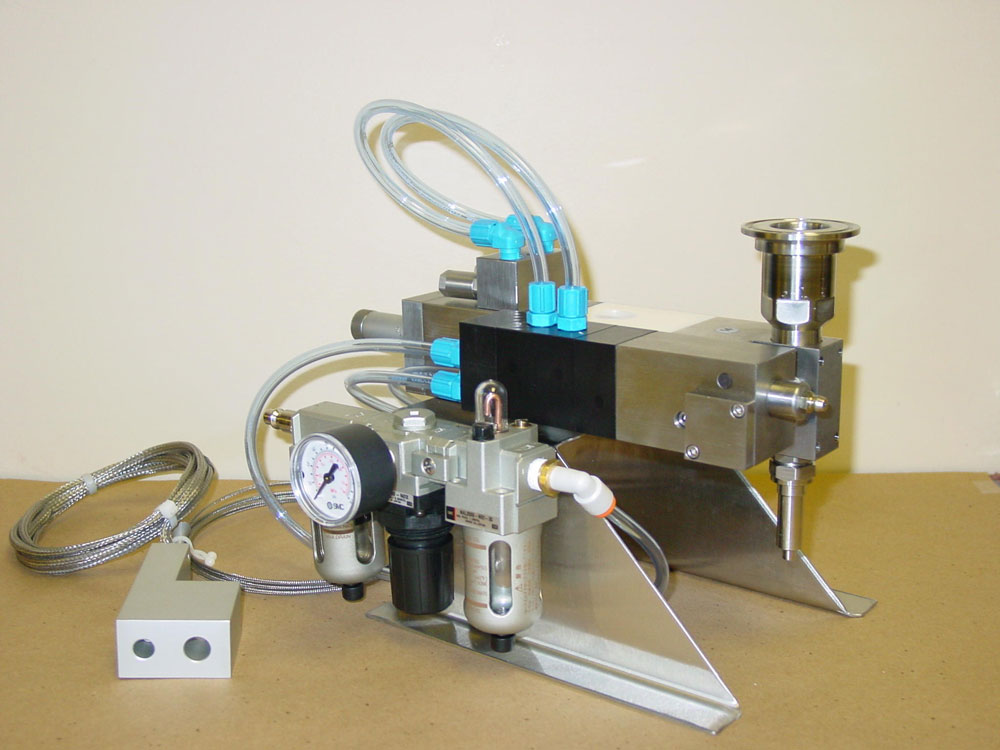

Heated Nozzle Assemblies:

|

|

|

|

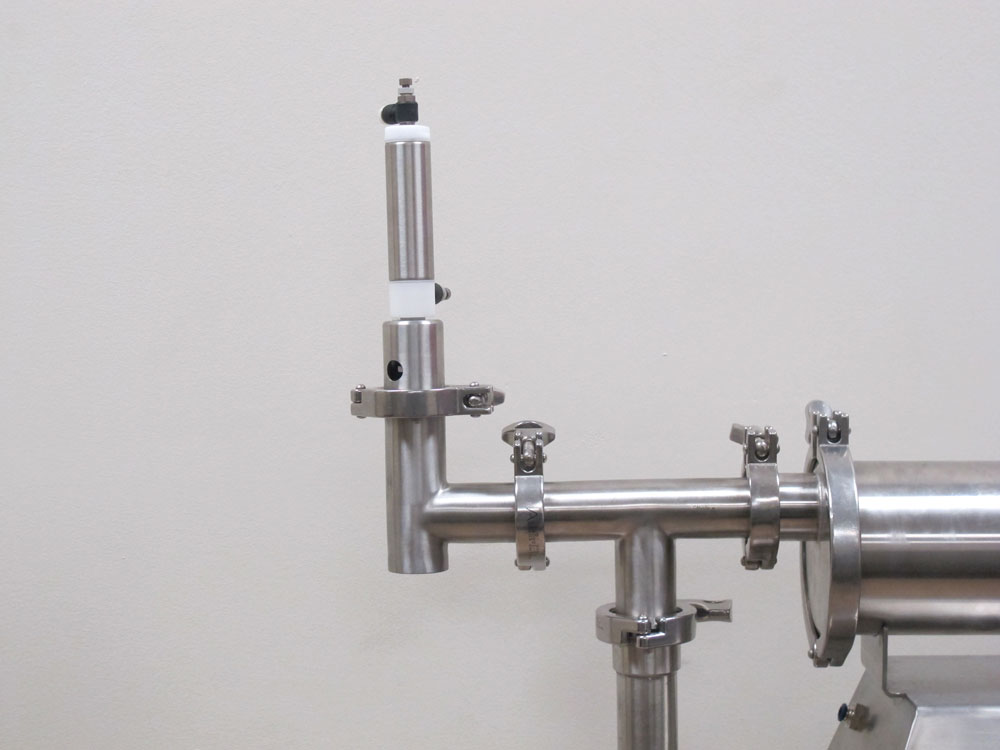

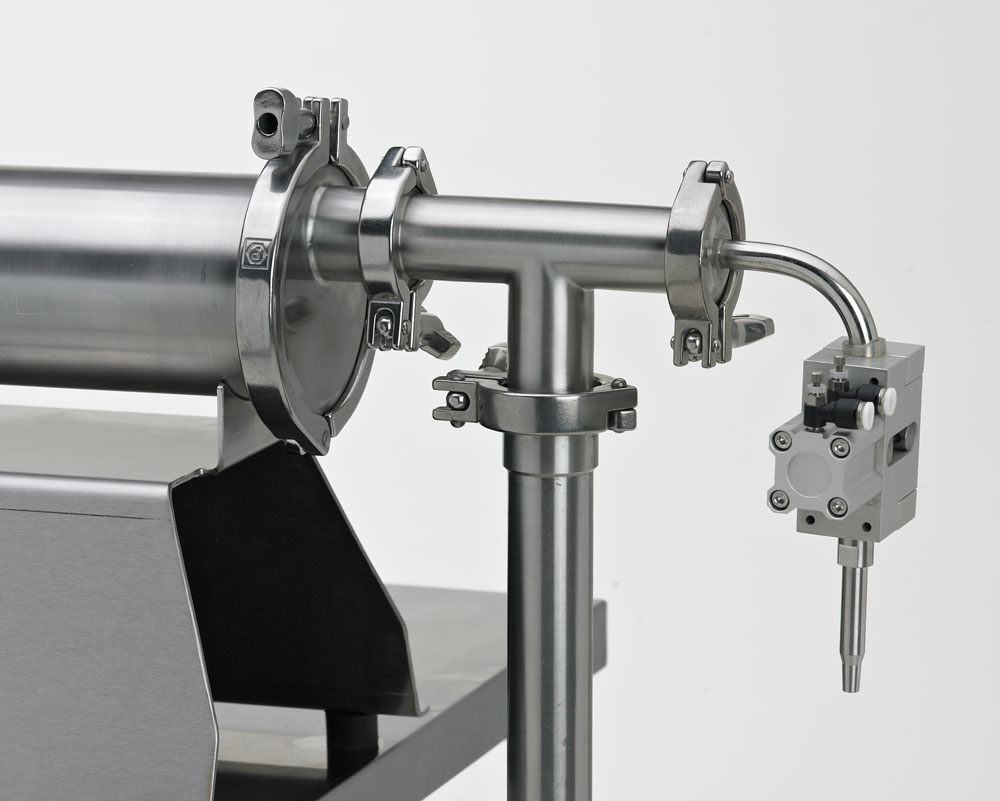

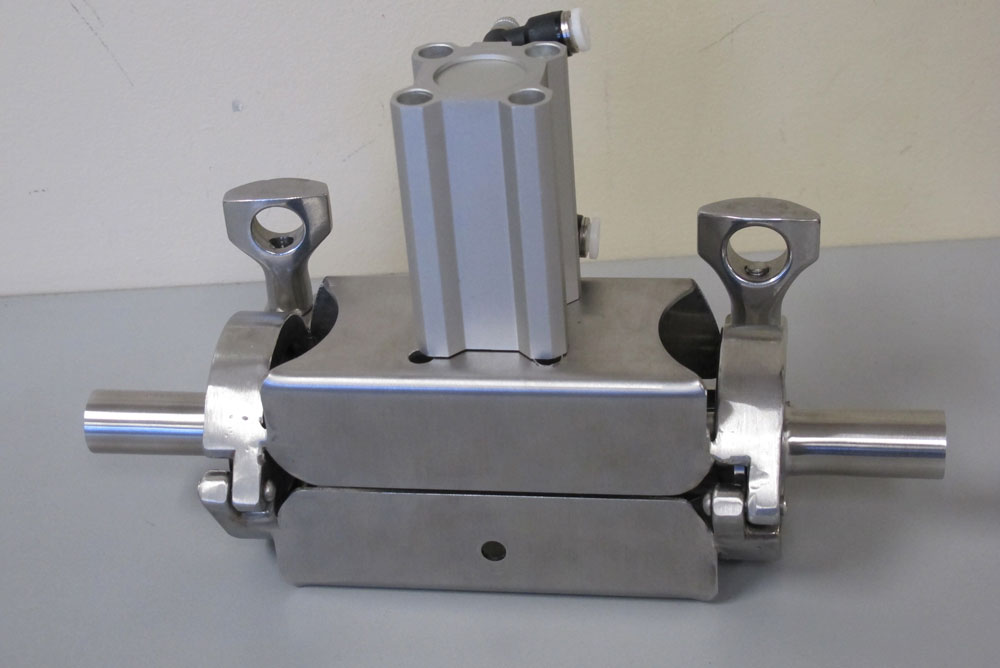

Actuated Sanitary Pinch Valve Nozzle :

|

|

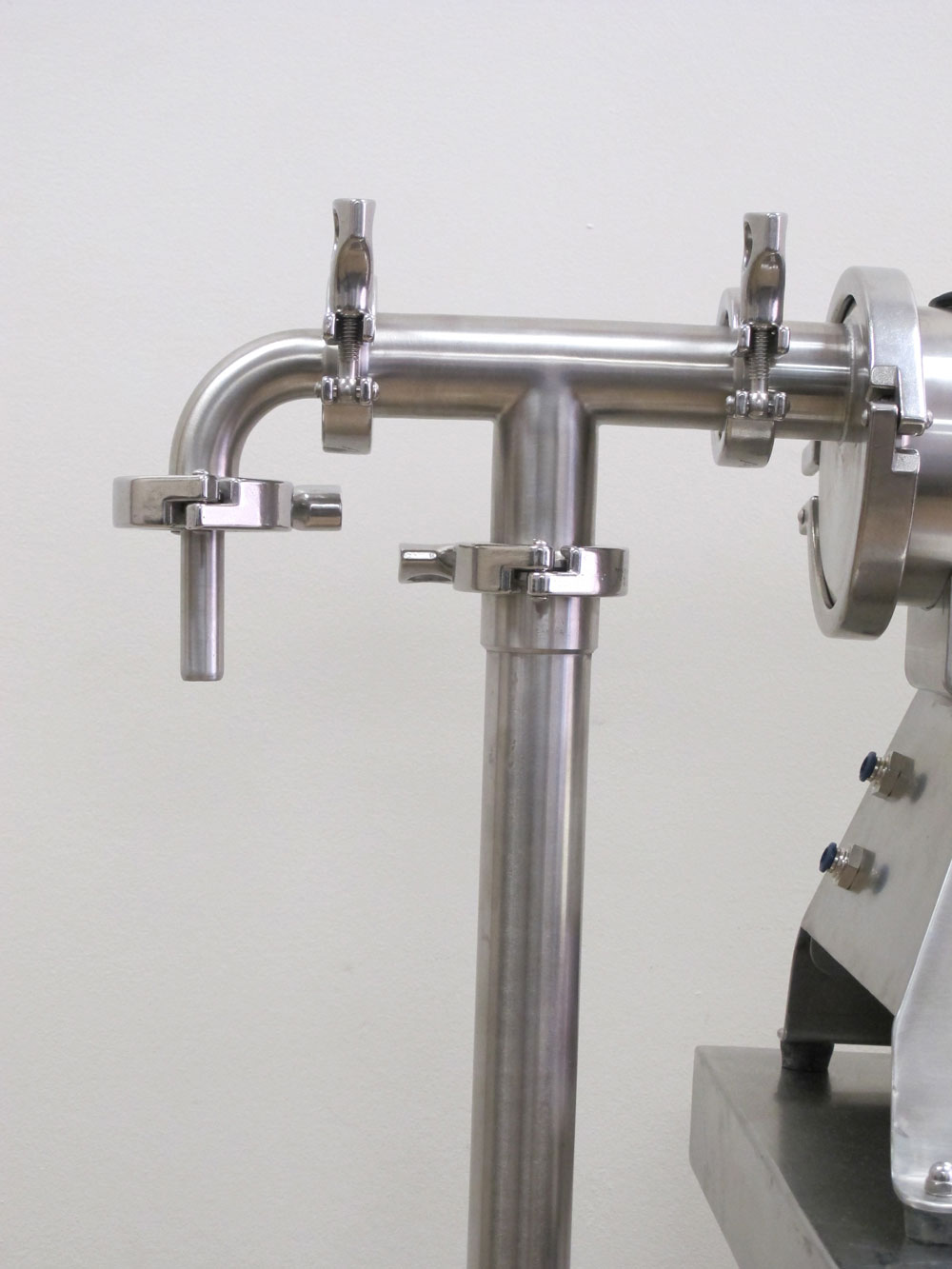

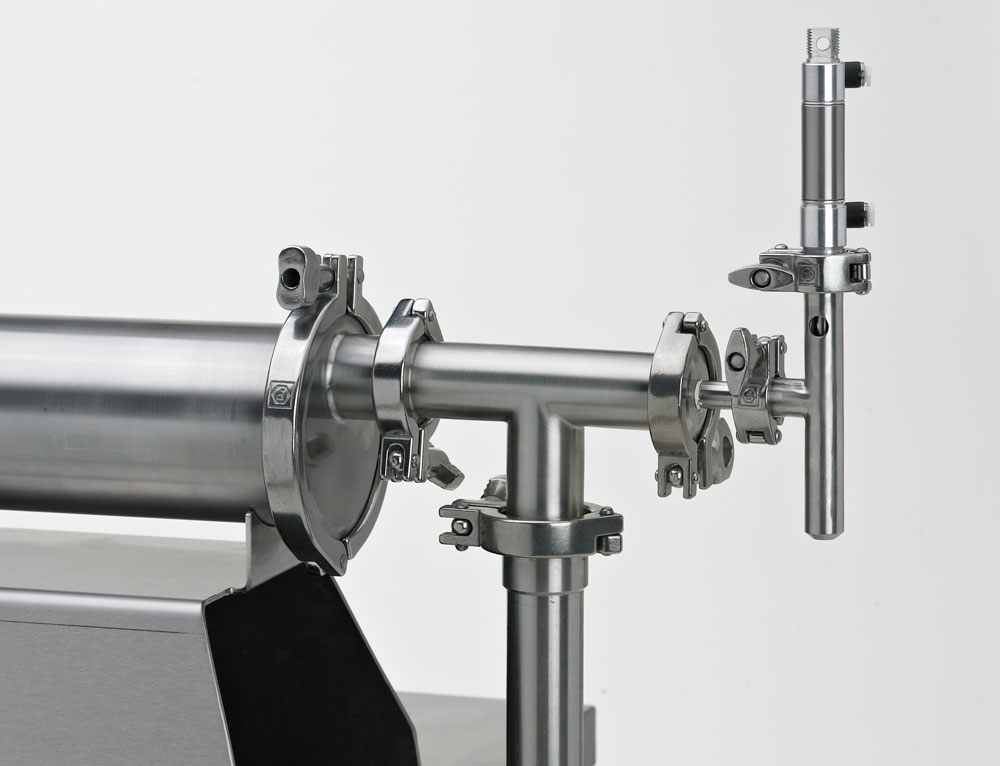

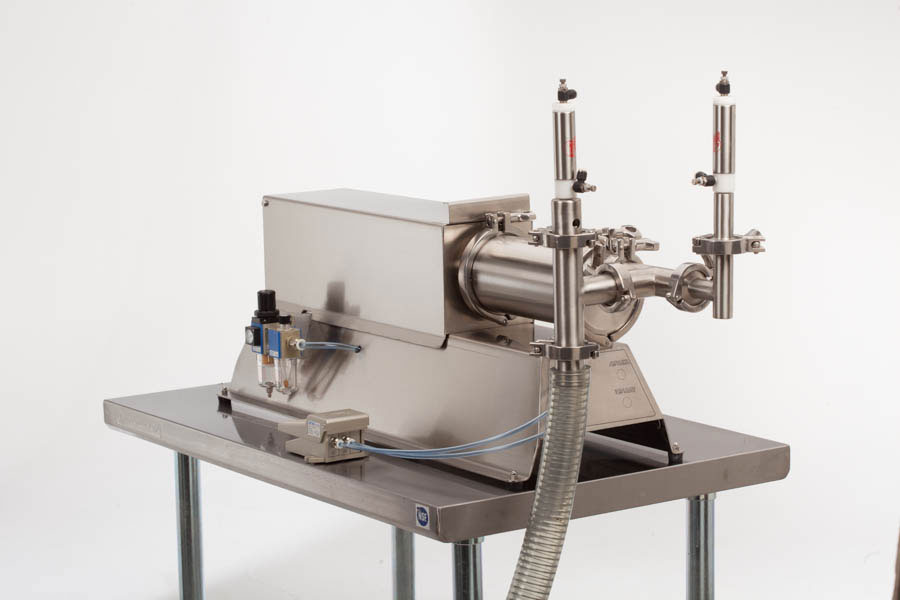

INTERCHANGEABLE: SDS Pump Head Inlet Valves

|

|

|

Big Port E-Z Flow Sanitary Check

|

|

Actuated Sanitary Ball & Butterfly Valves

|

|

|

Plug Spout Sanitary

|

|

Actuated Sanitary Pinch Valve

|

Actuated Commercial Valves

|

|

|

|

| SANITARY PINCH VALVE WITH TOOL-FREE-TEARDOWN

FEATURES: - 1 1/2” Tri-Clamp mounting with 3/4”bore Silicone Tubing

|

|